Eco PTFE Etched Tube: The Core Choice for Enhancing Catheter Performance

In the field of medical catheter manufacturing, performance and innovation are key pursuits for R&D teams. Eco proudly introduces our PTFE Etched Tube (PTFE Liner), an inner lining solution designed for high-precision catheters. With exceptional lubricity, durability, and processing flexibility, it empowers your products to stand out at the forefront of technology.

Why Choose PTFE Etched Tube?

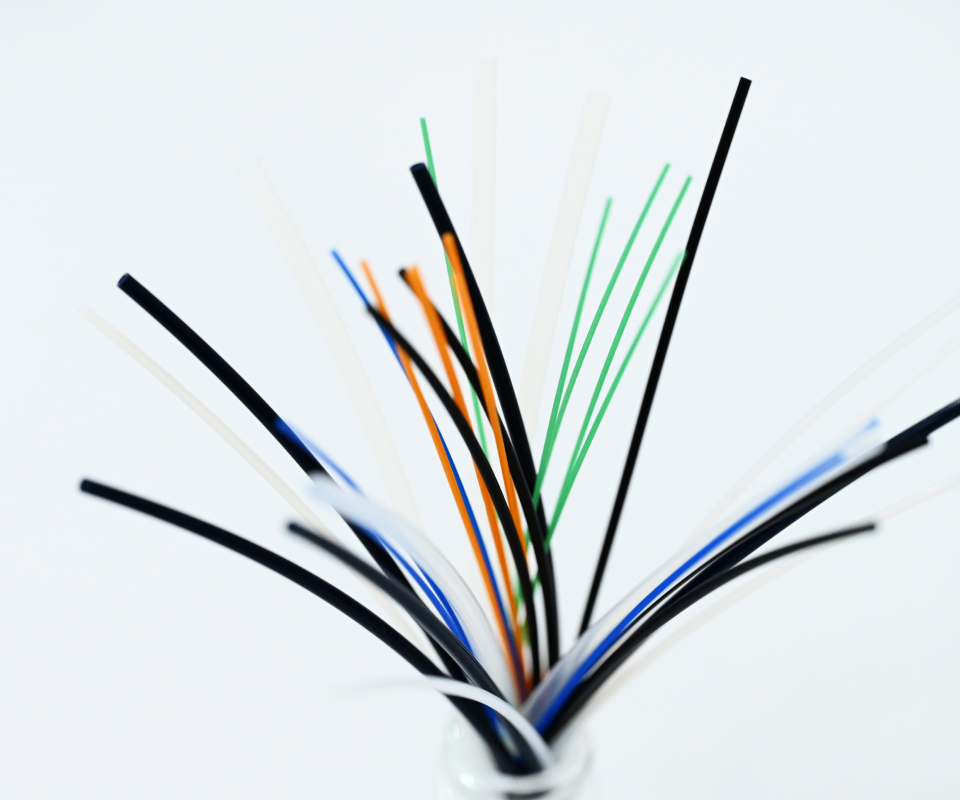

PTFE (polytetrafluoroethylene) is the preferred material for catheter linings due to its ultra-low friction coefficient, biocompatibility, chemical inertness, and ability to be processed into tubing with extremely thin walls and tight tolerances. Eco enhances its surface through an advanced chemical etching process, creating microscopic textures that improve bonding strength with outer polymers (such as nylon or Pebax), significantly reducing the risk of delamination. Compared to traditional unetched PTFE tubes, this enhancement delivers greater structural stability and durability, meeting the demands of high-reliability designs.

Technical Advantages, Empowering R&D

Eco PTFE Etched Tube offers R&D teams vast opportunities for innovation. We provide customization options for various wall thicknesses and inner diameters, accommodating diverse needs from minimally invasive interventions to large-scale delivery systems. Whether optimizing guidewire pushability or enhancing inner wall wear resistance, Eco delivers flexible technical support to accelerate your development process.

Application Scenarios and Market Value

Eco PTFE Etched Tube holds broad potential across multiple high-growth segments in the medical catheter field:

· Neurointerventional Catheters: The ultra-low friction surface significantly reduces guidewire push resistance, enhancing control precision in complex vascular pathways and meeting the demands of minimally invasive, highly sensitive neurointerventions.

· Coronary Artery Catheters: Superior wear resistance and chemical stability support repeated pushing under high pressure, extending device lifespan and aligning with the cardiovascular market’s high durability standards.

· Peripheral Vascular Catheters: Enhanced bonding strength ensures the integrity of multilayer structures during high-flow delivery, ideal for long-lasting peripheral vascular treatment designs.

· Urological Catheters: Chemical corrosion resistance withstands bodily fluid exposure, while the low-friction design minimizes tissue irritation, driving differentiation in the urological device market.

· Endoscopic Catheters: Thin-wall design combined with high lubricity supports smooth operation within endoscopic channels, meeting dual requirements for flexibility and reliability in endoscopic equipment.

From a market perspective, the properties of PTFE Etched Tube directly address industry trends—minimally invasive techniques, precision, and longevity. The neurovascular and cardiovascular catheter markets are expected to experience rapid growth in the coming years, with high-performance lining materials serving as a critical driver of this momentum. Eco PTFE Etched Tube offers manufacturers a chance to achieve technical differentiation, boosting product competitiveness in clinical applications.

Partner with Eco, Unlock the Future

As an innovator in the medical catheter industry, Eco not only provides PTFE Etched Tube but also commits to comprehensive collaboration, from material optimization to process support. We invite supply chain experts and R&D engineers to connect with us to explore how this technology can be integrated into your next-generation designs. Visit our website to request samples or detailed specifications, and let Eco propel your products toward market leadership.

Eco PTFE Etched Tube—lubricious, durable, reliable—empowering every step of catheter manufacturing.

Eco Polymer: Where Innovation Meets Excellence in Medical Device Manufacturing.

Contact us

As a leading Contract Manufacturing Organization (CMO), we excel in custom medical catheters and membranes, from prototyping to mass production. Our focus: unparalleled R&D innovation and rigorous quality validation.