FEP Heat-Shrink Tubing: A Core Material in Medical Catheter Manufacturing

In the field of medical catheter manufacturing, FEP heat-shrink tubing (fluorinated ethylene propylene heat-shrink tubing) stands out as an indispensable material due to its exceptional performance. With its low friction coefficient, high temperature resistance, chemical inertness, and excellent transparency, FEP heat-shrink tubing provides reliable support for high-precision catheter production.

Characteristics of FEP Heat-Shrink Tubing

FEP heat-shrink tubing is a high-performance fluoropolymer with superior physical and chemical properties. Its low shrinkage temperature (approximately 210°C) makes it easier to process compared to PTFE, with typical shrinkage ratios of 1.3:1 or 1.6:1, allowing it to conform tightly to complex catheter shapes. FEP also offers high transparency, biocompatibility, and chemical inertness, ensuring stability in demanding medical environments.

Eco can customize FEP heat-shrink tubing in various sizes, shrinkage ratios, and thicknesses to meet specific requirements, providing enhanced tensile strength, abrasion resistance, and other performance improvements.

Catheter

Wide-Ranging Applications of FEP Heat-Shrink Tubing

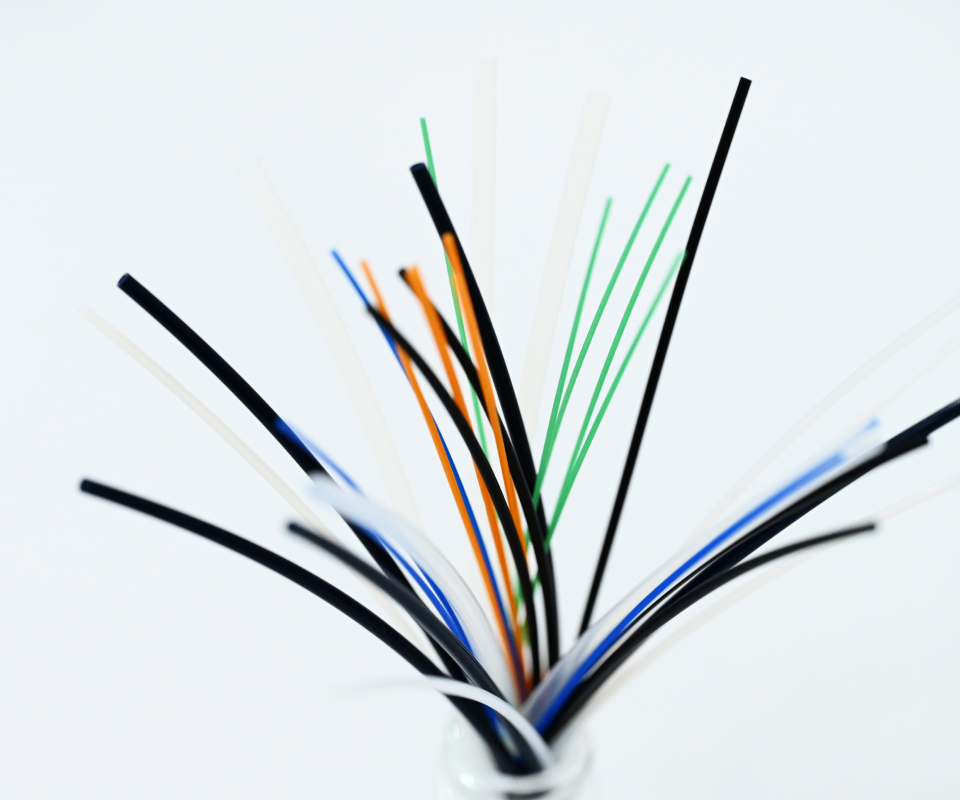

1. Processing Aid in Catheter Manufacturing: FEP heat-shrink tubing is used to fuse multilayer catheter structures (such as PTFE liners, stainless steel braids, and Pebax outer layers), ensuring strong interlayer bonding. Its high transparency enables real-time monitoring of weld quality, significantly improving production efficiency and product consistency.

2. Minimally Invasive Interventional Catheters: In vascular intervention, cardiac electrophysiology, and neurointerventional catheters, FEP heat-shrink tubing serves as a temporary outer layer to protect inner materials and assist in forming. Its easy-peel feature minimizes surface scratches, meeting the high-precision requirements of microcatheters.

3. Guidewire and Coating Protection: FEP heat-shrink tubing is used for guidewire encapsulation, providing a low-friction surface to enhance pushability and abrasion resistance while protecting internal metal cores from corrosion.

4. Other Medical Applications: FEP heat-shrink tubing is widely used in endoscope sleeves, drug delivery devices, and laboratory fluid transfer tubing, with its chemical resistance and transparency ensuring long-term reliability.

5. Customized Design: FEP heat-shrink tubing can be processed into ultra-thin walls (as low as 0.05mm), meeting the needs of miniaturized catheters, particularly in pediatric or neurosurgical applications.

Industry Value and Future Outlook

FEP heat-shrink tubing, with its multifunctionality, significantly reduces the complexity and cost of catheter manufacturing while enhancing product performance. As minimally invasive surgeries gain popularity, the global FEP heat-shrink tubing market is expected to continue growing, driving the development of more precise and reliable medical devices.

Eco Polymer: Where Innovation Meets Excellence in Medical Device Manufacturing.

Contact us

As a leading Contract Manufacturing Organization (CMO), we excel in custom medical catheters and membranes, from prototyping to mass production. Our focus: unparalleled R&D innovation and rigorous quality validation.